The modeling process for the scoops and ducts commenced with the utilization of a point cloud generated from a 3D scan. Our initial step involved considering specific boundary conditions, which encompassed the contour of the rear quarter window trim, the inner lining of the quarter side windows, and the original rollbar. Importantly, these boundary conditions remained consistent across both the 981 and 718 models. It should be noted that we also accounted for aftermarket rollbars in our analysis. The majority of these rollbars do not deviate from the stock height, thus ensuring compatibility with our system, provided they do not extend lower than the stock GT4 and GT4 RS models.

- -

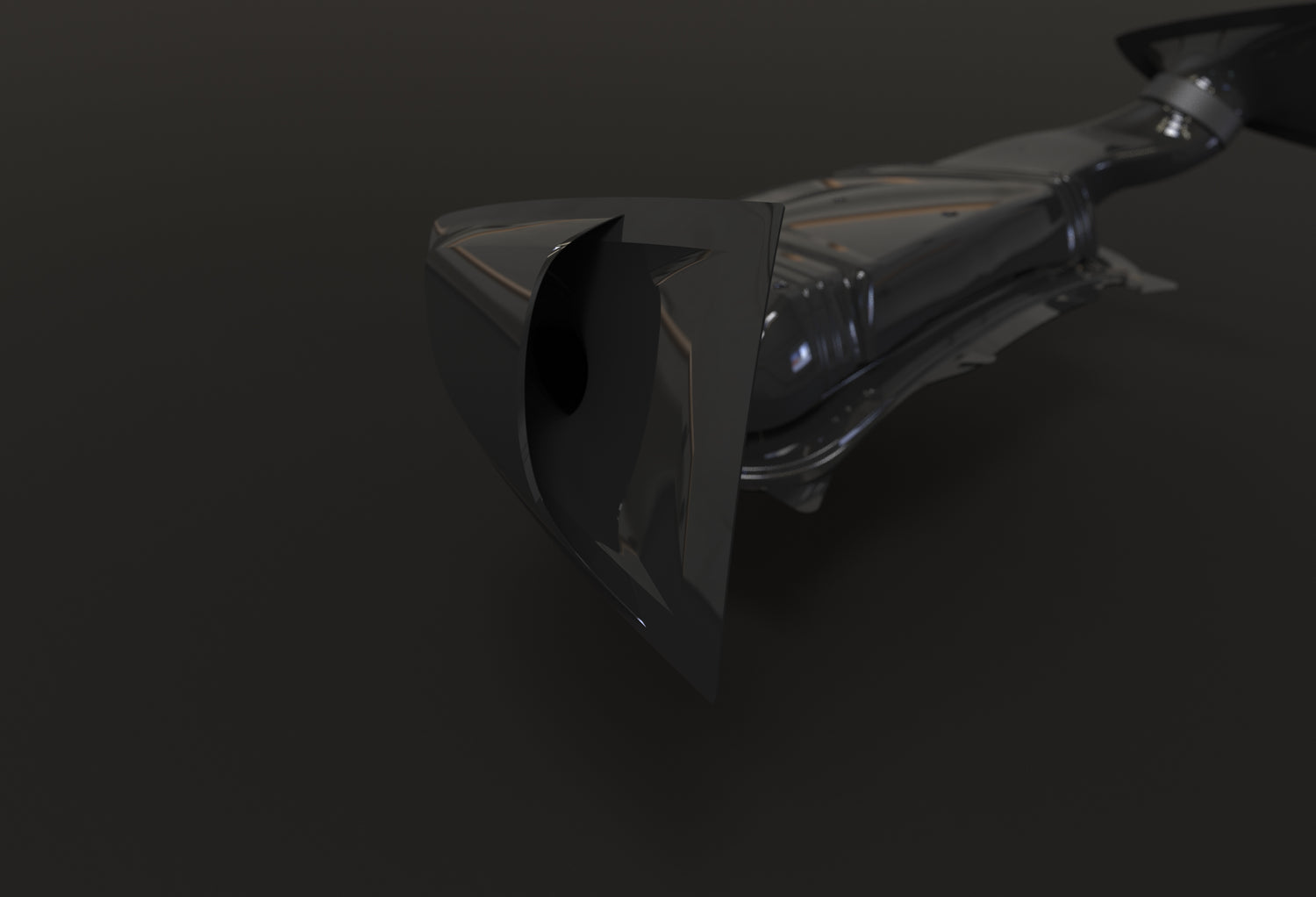

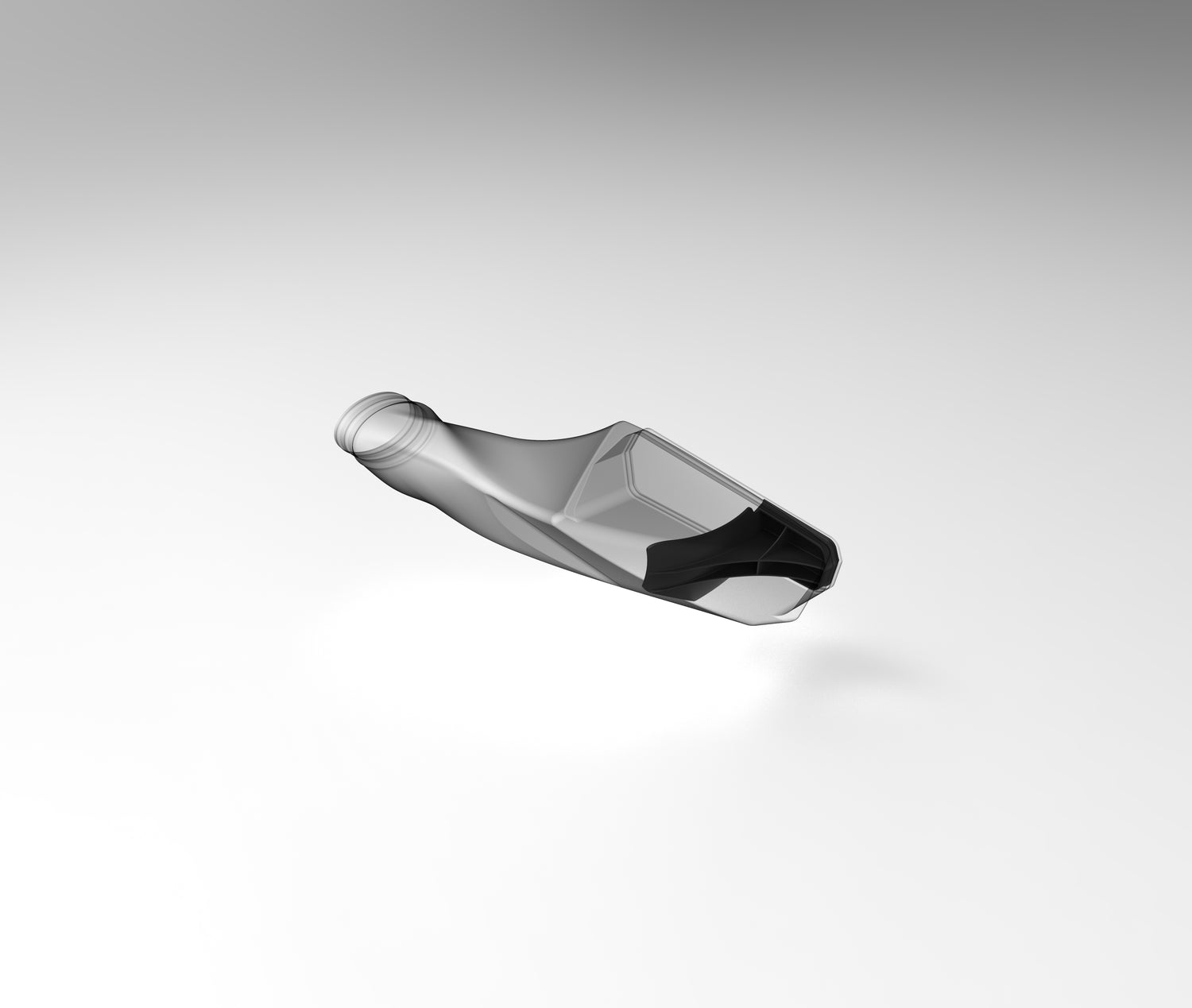

Our overarching modeling approach adhered to the principle of faithfully reproducing the original design while simultaneously enhancing functionality and adapting the internal components to accommodate the new air routing configuration. In pursuit of our objective to offer a fully reversible system, we made a deliberate choice to avoid any interior lining modifications, such as the cutting required in the original GT4 RS system. Consequently, we opted to shift the location of the duct opening slightly towards the front. This strategic decision led to the adoption of an oval-shaped opening, chosen for its advantages in terms of manufacturing efficiency, ease of installation within the vehicle, and superior sealing capabilities between the outer and inner duct components. The cross-sectional area of the oval opening was optimized to be as large as possible while maintaining a smooth contour to facilitate laminar airflow. This design decision also ensured compatibility with both the inner lining and rollbar. Importantly, the cross-sectional area of the ovals surpasses that of the intake cross-section of the Y pipe, resulting in a favorable pressure balance. The interface between the outer and inner ducts features a recessed coupling, resulting in a flush appearance with the connected pieces, thereby improving upon the original design.

- -

The scoop was designed to snugly fit within the same U-shaped rubber channel that was previously occupied by the rear quarter glass. To install the scoop, one can easily remove the glass from the trim using a heat gun, and then insert the scoop with a touch of silicone adhesive. It's important to note that the U-shaped rubber channel on its own ensures a secure and watertight seal.

- -

With the oval opening positioned slightly forward, we decided to enlarge the scoop, effectively covering a greater surface area of the outer ducts. This augmentation not only enhances aesthetics but also contributes to an increased ram air effect compared to the stock configuration.

- -

The inner ducts were meticulously maintained to closely resemble the original design, with adjustments made to facilitate the redirection of airflow towards the front of the central intake housing. The alteration in air routing will become more comprehensible once we delve into the description of the central intake housing. To minimize turbulence within the inner ducts, we incorporated 3D-printed inserts for precise air management.

- -

Tags: Porsche performance upgrades / Lightweight car modifications / Carbon fiber tuning / High-performance Porsche parts / Porsche exterior modifications / Aerodynamic Porsche parts / Luxury car enhancements / Porsche weight reduction upgrades / Racing-inspired Porsche parts / Track-ready Porsche upgrades / Carbon fiber wheel covers / Porsche 911 carbon fiber aero / Carbon fiber track enhancements / Performance-focused car modifications / Porsche racing aesthetics / Carbon fiber aerodynamic solutions / Weight reduction for Porsche / Carbon fiber driving experience / GT3 RS airflow optimization / Carbon fiber Porsche exterior / Best carbon fiber upgrades for Porsche / How to improve Porsche aerodynamics / Porsche 911 GT3 RS weight reduction / Porsche carbon fiber air intake benefits / Is carbon fiber worth it for Porsche? / Track-ready Porsche carbon modifications / Enhancing Porsche performance with carbon fiber / Carbon fiber exterior upgrades for Porsche 911 / Best Porsche carbon fiber air intake system / Carbon fiber aero kit for Porsche models